As we return to normality after a year of lockdowns, crises and disruption, a general mood of optimism has translated into businesses making bold and ambitious plans for growth.

However the re-opening of the economy has also brought it’s challenges. For product businesses, these are manifesting themselves in higher manufacturing and transport costs. While these pressures are likely to settle down over time, product designers can and should factor the commercial environment into their thinking, and find creative ways to reduce business costs without compromising on innovation.

Supply

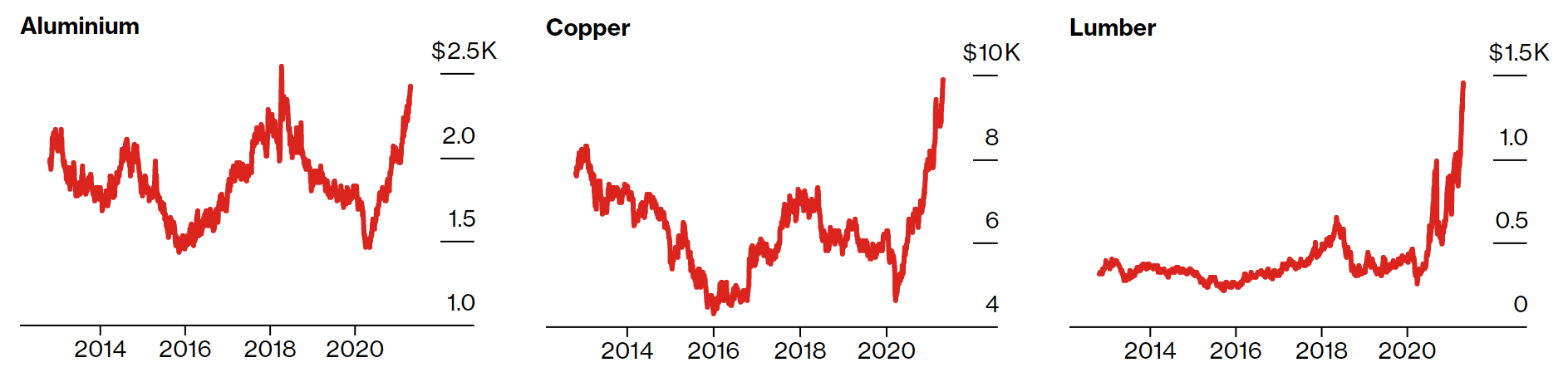

Every product starts with raw materials, and the price of these materials has risen significantly over the course of the last year. Although the cost of materials in a product is often much smaller than the cost of labour, these higher prices are likely to persist for some time and will make a difference to manufacturing cost.

Further to this, many manufacturers closed or reduced capacity in response to the disruption in the early days of the pandemic. However as life returns to normal, they are struggling to keep up with the surge in demand.

Credit: Bloomberg

Transport

Once a product has been manufactured, it needs to be transported. For a country like the UK this often means importing from overseas, and that relies heavily on the shipping industry.

Again, many businesses have seen rising shipping prices. The reasons for this are varied, but include the blockage of the Suez Canal and a rush from big retailers to re-stock after a year’s worth of supply chain disruption. For the UK, Brexit has also played its part in making it more difficult and costly to transport goods.

The good news is that this spike is likely to ease as more capacity comes online. Orders for new container ships for the first 5 months of this year outstripped demand for both 2019 and 2020 combined, but it will take some time for these ships to enter into service.

There are a huge range of factors at play here, but we identified and explained a number of ways in which design can help mitigate against them.

What Can Product Designers Do?

Achieve more, with less

Although it’s one of the most obvious challenges, this is also one that requires a lot of careful thought and creativity. On a basic level, reductions in material weight and thickness will help reduce part costs. However the real benefits will be found when designers push to find the simplest possible solution to the problem a product is trying to solve. Simple solutions are not only cost-effective to manufacture, but they are often easier to communicate to customers.

Use design to increase ROI

It is the responsibility of the designer to generate ideas that are meaningfully better and more valuable than what’s already out there. These ideas might come in the form of a new invention, a better user experience, improved build quality or an aesthetic improvement that resonates with customers. In any case that design value can enable businesses to increase sales volume, increase prices, or both.

Consider shipping during design

While shipping sizes shouldn’t stop you from finding the right idea, designers can considerably streamline shipping logistics with some relatively simple decisions during the development process. For example, a larger draft angle could become both a design feature and also allow parts to stack together for transport. Or is there a way to make it easy and safe for a customer to assemble some parts themselves?

Map out the options

Every product or product range is likely to need a selection of versions (or SKUs) to suit different people. However it’s also important to reduce the number of SKUs as far as possible to simplify the practicalities of ordering, storing and shipping these options. This is where strategic thinking and planning at the start of the project can pay dividends later down the line. Designers have a strong understanding of user needs and are well-placed to help set this direction.

Think long term

It is also important to think ahead and build a strong innovation roadmap that gives businesses flexibility to respond to changing market conditions. If there is only one product in the pipeline, or the current product offering is getting dated, it’s possible that time pressures will result in businesses needing to absorb costs that could otherwise be avoided. Product designers are responsible for looking ahead and anticipating what the target market will want next – resulting in a healthy roadmap that gives businesses both time to prepare and the flexibility to change course without incurring large costs.

Despite the temporary cost pressures associated with manufacturing and logistics, product designers can factor this into their thinking early on and use their creativity to find ways of reducing cost and increasing efficiency.

Want to know more?

Tone is a London based creative product design agency. If you’d like to talk to us about what we do or tell us about a new project, send us an email at:

We’d love to hear from you.

Read more of our news

The impact of right to repair legislation: re-thinking product design

It seems a reasonable expectation that consumers should have the right to repair products they have purchased. But it has become increasingly difficult, if not impossible, to repair most of the electronic devices we own. The ‘right to repair’ movement aims to fix our relationship with electronic device consumption and make certain products more easily repairable and durable.

Read more